Handle

Handle 1Jikutame

Make a handle straight on an electric heater by using an instrument called 'tamebou'. When other makers make Japanese-style paintbrushes, they farm out to produce bristles, holders, and glue attachment to final products to subcontractors. Seishindo does all procedures including handle attaching in own workshop.

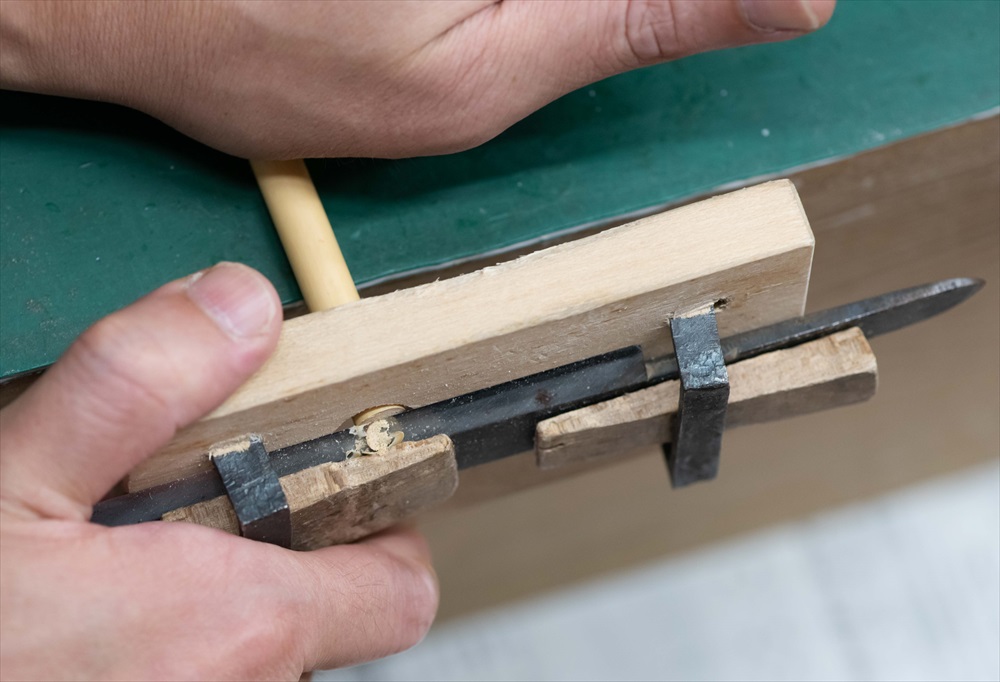

Handle 2Jikukiri

Cut handles by electric-cutter. Making brushes require many handworks. The only changes are to use an electric-iron from an iron file heated on charcoal, and an electric saw from hand saw.

Handle 3Toudurudume

Put wister vine at the end of the holder to improve holder's strength.

Handle 4Kannagake

Make suface flat and smooth by a tool at the heel of handle.

Handle 5Mentori

Arrange head-shape of handle. Handle is ready now.

Handle 6-1Shirikiri

Cut at the heel of the bristle to fit in the handle.

Handle 6-2Kurikomi

Smooth inside of the handle to set the bristle well.

Handle 7Secchaku

Put glue into a handle head and adjust the length of the bristle.

Handle 8Funoriire

Add natural glue (made from seaweed) in dry brush.

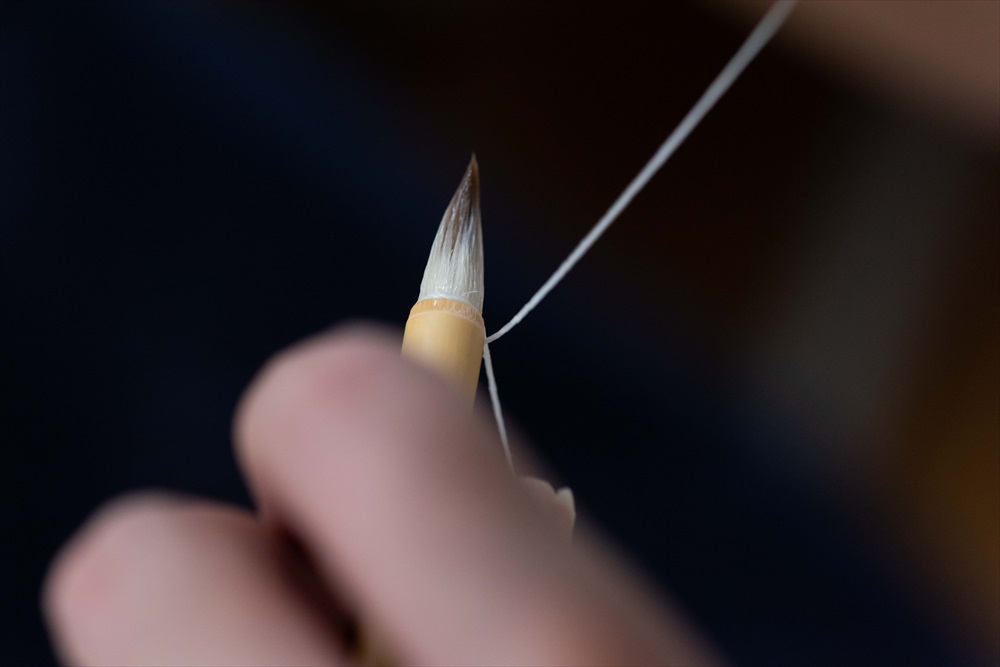

Handle 9Shiage

Take off natural glue by string and arrenging the shape of the brisle.

Handle 10Finish

Dry the finish product slowly.

Handle 11Naire

Finally put a celluloid cap and name on the handle.